Keeping always an open eye for new and innovative products, it was in the beginning of 2012 when the completely new Sunwayfoto Low Profile XB Series of ball heads captured my attention, as one of these might be a possible answer to my seeking of a low weight, well balanced, smoothly operating at any angle, yet sturdy ball head.

Keeping always an open eye for new and innovative products, it was in the beginning of 2012 when the completely new Sunwayfoto Low Profile XB Series of ball heads captured my attention, as one of these might be a possible answer to my seeking of a low weight, well balanced, smoothly operating at any angle, yet sturdy ball head.Last February, SUNWAYFOTO® introduced their new XB Low Profile series to the public, in "2012 PMA@CES", in Las Vegas, U.S.A., raising once again my interest on the product.

Having had a good experience with the Sunwayfoto DB-36TRLR Traveler ball head urged me to know more about the XB series.

My request for more detailed information on the new Low Profile XB series, led to an invitation by Sunwayfoto headquarters to participate in their Test & Review Program released early last March, which I gladly accepted and applied for. That in turn led to the delivery of a small package at my door by DHL at the end of last April.

The above introduction aims to point out that the XB-44 Low Profile ball head under review is a complementary sample provided directly by Sunway Opto-Electronics (Group) Ltd, in China, for the exact purpose, and for which I paid only for the appropriate import duties and taxes.

Sunwayfoto's course up to now shows clearly their intention to be at the top with the market leaders. Through my little experience with other Sunwayfoto products, their precision, their innovation but also their pricing definitely declares the market placement.

Aiming to the top, makes it far more difficult to build a name, as the competition gets harder.

The recommended retail price of US $ 330.00 for the XB-44 Low Profile ball head places it at direct competition with RRS, Markins and Photo Clam to name a few, who have similarly priced products with a 40-44mm ball. But on the other hand the Low Profile design limits the competition between only two other rivals (at least to my knowledge) that follow the same design concept, these are RRS with BH-40 and Induro with BHL-2.

RRS follows a premium pricing marketing strategy with a US $ 356.00 tag on the CNC machined BH-40 (with screw knob clamp) while Induro (Benro's high end product line for the U.S.) follows the discount path with a tag of US $ 267.00 on the Die Cast BHL-2.

Somehow the low profile design similarities stop here, as both RRS BH-40 and Induro BHL-2 have open clamp (calliper) design, obvious from the seam on the back of their body shell. To put it simply, the ball movement is controlled by the pressure exercised on it, the more the two parts of the body are brought closer together.

Sunwayfoto XB-44 design differs greatly from the other two as it has a completely closed CNC machined body shell, with an internal ball control mechanism which I'll try to describe later on, and that's it. It's a unique in concept fusion between Arca Swiss® classic design and a low profile calliper design, applied for and patent pending.

How well is the concept implemented, we'll see in the following review.

One of the things I have learned from my tutors early in life, is that in order to excel in any field except from knowledge, endeavor and stamina, persistence in detail is also a factor that will discriminate one from the mass and put him/her at the top with the Elite.

Therefore, I intend to be more persistent and strict with detail in my review, so as my comments may give room for improvement.

The Package & Contents

At receipt of the package, after opening the "travel outfit" (the standard DHL envelope and an extra carton box), I was expecting to see the usual up to now Sunwayfoto "luxury" black box with the golden rims and lettering, but I realized that Sunwayfoto has changed into a more environmental friendly attitude by enclosing the XB-44 Low Profile ball head in a thinner and lighter, recycled carton box.

As I was later informed, from now on all Sunwayfoto ball heads, monopod heads and leveling bases will be shipped in similar recycled carton boxes. In one way this gives me a hint that emphasis is now in the content rather than the box. Although I suspect that the black and gold boxes will be kept for special occasions, like anniversary editions etc.

|

| While there is a small label with the model number on the front, one side of the box is covered with a big white label with technical specification a picture and the barcode of the product. |

|

| The XB-44 Low Profile ball head travels in the box within thick foam padding together with ... |

|

| A credit card sized warranty Card stating Model and Serial Number (which in my case is followed by the word SAMPLE and the sample number)... |

The Ball Head

|

| The dimensions of XB-44 and the larger XB-52 ball heads (Photo by courtesy of Sunwayfoto). |

| Manufacturer Specification: | |

|---|---|

| Model: | XB-44 Superior Low Profile |

| Ball Diameter: | 44 mm |

| Pan Base Diameter: | 58 mm |

| Bottom mounting thread: | 3/8"-16 UNC |

| Height: | 79 mm |

| Weight: | 483 gr* |

| Max Load capacity: | 40 kg |

Note: The verified weight of the XB-44 ball head copy I received is 465gr on my electronic scales, just a little better than the 483gr stated in the manufacturer specification.

|

| By removing the conversion bushing the ball head is ready to be mount on a standard 3/8"-16 tripod stud. |

The ball & Controls

XB-44's ball follows the Sunwayfoto standard of their ballhead balls being ellipsoidal but closer to spherical form than balls made by other manufacturers. At present, on most ellipsoidal ballheads in the market, the Y-axis diameter of the ball is about 0.07mm longer than the X-axis, in order to compensate for the extra torque generated when the ball is tilted to the side, by increasing the friction and thus avoid the risk of drift or drag.

On Sunwayfoto ballheads the ball Y-axis diameter is 0.03mm longer than the X-axis, aiming to a smoother operation, while retaining the previous advantage.

The Quick Release clamp

The screw knob Quick Release clamp is especially designed to fit the Sunwayfoto XB-44 ball head, both in dimensions and optically.

There are 2cm long laser engraved decimal scales on both jaws, the first cm closer to the center is marked in 1mm increments and then in 2,5mm increments, with numbers every 1cm from 0 to 1 counting outwards. There are two safety stop screw relief grooves 5mm deep, one at each side, permitting a motion of 15mm either side into the clamp, for better camera/lens plate alignment. On the outer jaw opposite the screw knob, exists a 12mm spirit bubble level which is bright and accurate.

Clamp's dimensions: jaws length 48mm, width 86mm (including the screw knob and the bubble level), thickness 14mm.

|

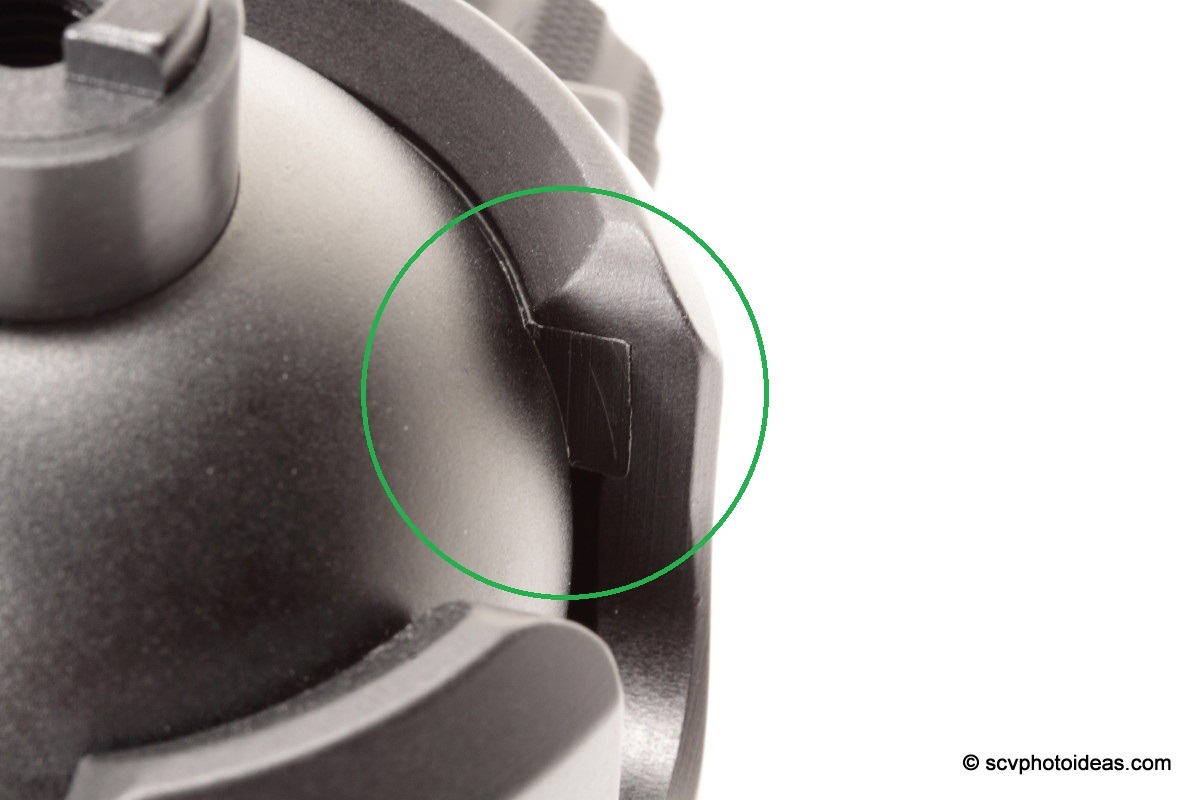

| Another very fine detail is the thickness and precise positioning of the Teflon insert around the top body perimeter. |

Removing the Bubble level

In this way, the bubble level can be attached either to the right, or to the left side of the screw knob.

Somehow, attaching the bubble level on either side, blocks the corresponding safety relief groove. This may prove a restriction if someone uses camera or lens plates with M3 safety stop screws installed at both sides of their bottom.

Nevertheless, this once again is a matter of choice and personal preference.

Mounting the Ball Head on a Tripod

The greatest benefit when using a Low Profile ball head is that it lowers the center of gravity of the mounted gear closer to the summit of the pyramid formed by the legs of a tripod.

This results in better stability and less vibrations which can be easily realized in practice without the use of special measuring equipment.

Any type of tripod, meaning with or without a center column will benefit from it.

Further on, I shall try to elaborate a little on the matter of the combination of tripod legs with the XB-44 Low Profile ball head.

Due to the very low profile of the ball head, something that has to be taken into account when mounting it on a tripod, is that the bubble level goes lower than the panning base of the ball head, when the quick release clamp is tilted fully at 90 degrees into one of the drop notches. Therefore, if you intend to use it on a tripod with a larger top plate than the head's base or on a tripod without a center column like a Gitzo® GT3542 Systematic, the bubble level must either be removed or relocated to one of the QR clamp's sides.

|

| My first choice was to mount the XB-44 ball head on the Benro A-298EX Versatile Tripod on which I have worked quite a lot, knowing its strengths and weaknesses well. That would immediately show if there was any substantial improvement by the ball head. And it actually did prove a more stable and vibration free solution. It also showed to me which limitations were to be assigned to the tripod and which to the ball head. XB-44 fits nicely on the tripod's top plate which has the same size as the ball head base. |

So what would be a good tripod leg combination with XB-44 Low Profile ball head?

That depends on what gear one wants to mount on the head of course, in terms of weight and lens focal lengths.

Putting down the ball head bearing weight capacity and stability combined in a compact low weight structure, I would say that a series 2 tripod* would benefit from the ball head giving an easily transportable solution, for lenses up to a 300mm focal length.

On the other hand, while increasing the total weight, a series 3 tripod* would enhance the ball head's attributes to the max.

*Standards being set by the leaders, I boroughed Gitzo®'s terminology of Series 2, 3 etc for tripods referring to largest leg diameter of 28mm, 32mm, and so on. Somehow, keep also in mind that a tripod's smallest leg diameter plays a significant role too.

|

| Sunwayfoto XB-44 posing on top the Benro A-298EX in the bright sun. |

|

| So bright, that had to lower the "hat" to protect the "eyes". "I look smart, Don't you think? " :) |

Using the Ball head

There was not sufficient time to use the ball head extensively since its arrival on April 25th but still, I'm in a position to comment on some of the excellent characteristics and some of the restrictions of this ball head.

First I can say that the hard coat mat anodizing on the ball head shell is excellent, it is non reflective, does not show hand / finger prints and is scratch proof.

Second, the stability of the ball head is exemplary under any load, even not fully locked and left at a "sweet spot" friction point when shooting. The ellipsoidal form of the ball is a great advantage. That means there is no need for much lock knob manipulation once you find a sweet spot for the camera lens combination in use, as the ball takes it from there and compensates for the increased torque when tilting. When the circumstances bring the need for locking it, e.g. strong wind, fully locking the ball the drift is unnoticeable, I have only noticed a tiny drift when shooting with a 400mm lens (640mm equivalent on 1.6x FOVCF) which compared to other ball heads is insignificant.

Vibrations even purposely induced on the tripod or the camera, fade out really fast so even if you don't have a cable release handy, shooting with a 2sec delay can give excellent results.

The ball operation is smooth out of the box. However, after a little running in for a couple of days it became even smoother, maintaining the same characteristics under different loads, balanced or unbalanced on the head.

The large control knobs, combined with the innovative ball and base control mechanisms, are very soft in operation requiring less force than I am accustomed to with other ball heads, so that I had a tendency to over tighten them in the beginning. But more on this a little further down.

Next, I shall go deeper into detail, for some characteristics I feel that need some improvement so as this ball head would be considered excellent in all aspects. Before reading further, everyone has to understand that a Low Profile design imposes some designing restrictions by itself. As with all things, there are some advantages and some disadvantages but for the sake of extra stability some compromises have to be made.

|

| (Photo by courtesy of Sunwayfoto.com) |

I can't come up with a probable solution for the interference with the large Friction/Lock knob though. Even the utilization of a much longer stem for the screw knob, as other manufacturers do, (much longer than the original design screw knob which had a stem, as depicted in the Sunwayfoto web site - photo left), could not override and stop the QR screw knob or its stem interfere with the large knob.

Only by raising the ball stem significantly would do the trick (another manufacturer solution) but this would sacrifice all the stability the extra low profile offers. No thanks.

Now coming again to the matter, regarding the corners of the QR clamp interfering with the Friction/Lock knob, that also occurs in another case bellow.

There are three suggestions I may address to Sunwayfoto engineers for the solution of the annoying interference of the QR clamp with other parts of the ball head.

a. Raising the height of the ball stem only by 1-1,5 mm would give the clearance to the XB-44 dedicated or any other clamp like the DLC-50 Lever release clamp to function better not hitting the panning base. This would not affect the ball head geometry match, but still it would not stop the clamp's corners from hitting on the Friction Lock knob.

b. Further trimming or rounding the corners of the XB-44 QR clamp either only at the bottom or fully would give it enough clearance all around, both with the Panning base and the Friction/Locn knob, while it would maintain the maximum clamping area.

c. Finally, creating a totally new dedicated 54mm Discal Clamp like the DDY-64 would solve all the interference problems of the rectangular clamp corners. Due to the circular shape it would decrease the clamping area a little though. As I said before, we can't have it all...

Last but not least on the usage experience of the XB-44 Low Profile ball head, are the control knobs. Based on my recent experience with Sunwayfoto DB-36TRLR Traveler ball head , which despite its small size has a very smooth and very gradual Friction and Panning control, which I would describe as more linear.

I was expecting something similar from the XB-44 Low Profile ball head, but mainly due to the design difference in the ball and panning lock mechanisms, things are a little different here. First, the larger knobs with their longer radius require less force to turn. Second, both the ball and panning lock mechanisms by design require less force to close and capture the ball or panning base respectively, in the beginning and stiffen as they reach the end of the knob drive. Therefore, the feeling you get by operating these knobs is very soft in the beginning but gets quite stiff towards locking. But let me elaborate a little on each one separately.

If you are used to other ball heads you might tend to over tighten the knob as I did in the beginning. Actually this is the most usable range for most medium weight camera/lens combinations or heavier combinations balanced on the lens collar foot. For example at the 12 o'clock position (one full rotation of the knob) the friction mechanism can immobilize a Canon 50D+70-200 f2.8 L IS USM clamped on the camera base plate (not balanced on the lens foot) at any angle!

However, after one full rotation and for another 1/2 rotation, things get really tough. Turning the knob requires much more force as it becomes really stiff. When this point is crossed, is hard to make fine adjustments and by turning the knob counterclockwise to loosen the ball a little bit, the knob turns abruptly more than required, while the locking mechanism does not respond immediately. It shows a latency to open and loosen and may require more turn of the knob to unlock or the ball has to be moved helping it. In anyway the frame is lost and needs readjustment.

The reactions of this new locking mechanism remind me of a strong wild animal but with great potential. Sunwayfoto engineers have to tame it a little. In my opinion this can be done, playing a little with the thread length/density of the screw that controls the mechanism, so as it becomes less soft in the beginning and less hard towards the end, in one word more linear and gradual. Further, I would suggest the consideration of using a spring as a counter force to help the faster release of the locking mechanism when tighten too much, in combination with use of a higher density (more sticky) silicone paste for the lubrication of the knob screw threads in order to dampen the abrupt jump when trying to unlock.

Torque Test results

Having had a limited time not only to perform all my tests on XB-44 Low Profile Ball Head, but also write down and document -a task that takes longer than anticipated- I can only say here that the ball head passed easily all preliminary load, ball and pan lock torque tests, just to prove that manufacturer specification is up to par and not only!

The maximum measured Torque of approximately 205 Kgf*cm (~2010 N*cm) is compliant to the maximum load of 40kg as declared by the manufacturer (measured directly on the ball head). This locking strength combined with the exemplary stability of the head can signify that lenses up to a focal length of 500mm can be handled. For this estimation I take into account lens lengths and weights.

To be on the safe side I would recommend the ball head for lenses up to 400mm f2.8. Maybe the ball head can cope with more, but for longer focal length and heavier lenses, using the larger XB-52 model will be more beneficial in many aspects. All the above are valid, given a quality, vibration free tripod, is used as well.

|

| This is the low resolution sample of a photo, shot on the full moon night of 05/05/2012, from the rooftop of a 10 stories building. It was a clear night with a slight breeze (Click to enlarge). Equipment used: Canon 50D + EF 100-400 L IS USM mounted on the Sunwayfoto XB-44 ball head by the lens collar foot + Arca plate directly, without any Long Lens Support Bracket. Focal length 400mm (Equivalent to 640mm on 50D's crop factor ), ISO 100, f 11, exposure 15sec!, No shutter lockup, 2 sec delayed timer. Distance from subject approximately 1,8-2,0 Km (1.12-1.24 miles). There was no other manipulation on the original raw file except for a slight increase in contrast and sharpness as I shoot with the neutral template. That's stable enough for me. If you have enough bandwidth you may view here a High Resolution version of the photo above. For a few more sample photos you may have a look at the 99.5% Full Moon Night... in Albums. |

Pros

Innovative and original design.

Exceptional machining, finishing, fitting and build quality.

Compact size and low weight.

Great stability and vibration absorption.

Very good panning friction control that permits fine tuning until a very strong panning lock.

Very smooth ball operation at all angles when a "sweet spot" is reached.

Good value for money ratio.

5 year limited warranty extension upon registration.

Cons

Limitations in Quick Release Clamp design that need reevaluation.

Friction /Lock control mechanism with long gap until to start locking the ball, leaving little space for fine adjustment.

Friction /Lock control mechanism does not un-tighten smoothly from full lock.

Conclusion

Having in mind that this is a newly released product with an innovative approach to the low profile design, some operational irregularities or small design flaws that need improvement may be expected.

Sunwayfoto's public Invitation for testing and reviewing the new XB ball head series, declares a company that lacks arrogance and accepts well intended criticism for the betterment of their products.

On the other hand a few minor flaws cannot obscure the built quality, the great stability and the smoothness of operation under different loads.

Therefore, I consider the XB-44 Low Profile Ball Head a top product, which after a little refinement yet may be ranked above competition.

Disclaimer:

This review and test was run on a single product sample, using the specifically described methods. Although the findings are good and some overcame the expectations for the product, it can not be used as a rule, unless more samples of the same product are tested. Furthermore, similar comparison tests should be run with comparative capabilities products so as to reach a solid conclusion.

As this is a very innovative and interesting ball head design, I got carried away with the length of this review. I apologize and hope you found the article interesting and useful, thank you for viewing and your patience if you read so far.

Update: July 2012

Update: July 2012

XB-44 Low Profile ball head is now available also as model XB-44DD2

with a DDH-02 Panning Clamp

Update: August 2012

Update: August 2012

A Useful Friction Tool by Sunwayfoto

Update: October 2012

Sunwayfoto XB and FB Series Manuals Available for Download

All Photos & Photosynths: © 2012 S.C.Vlachos

Photos by courtesy of Sunwayfoto.com are individually tagged.

Availability:

The Sunwayfoto XB-44 with standard screw knob clamp, or model Sunwayfoto XB-44DD2 with panning clamp are available from Amazon or from eBay worldwide.

Meanwhile, as of 2022 you may also purchase directly from the Sunwayfoto Store starting from US$ 199.00 for the XB-44, US$ 219.00 for the XB-44DL and US$ 239.00 for the XB-44DDHi.

Please note that we may earn a commission from qualifying purchases through above affiliate links.

Relevant Articles:

Sunwayfoto DB-36TRLR Traveler Ball Head Review

Sunwayfoto DLC-42 Duo Lever/Knob Quick Release Clamp Review

Benro B-2 Ball Head Review

Triopo RS-3 Ball Head Review

Referenced Articles:

Benro A-298EX Versatile Tripod Review

Sunwayfoto's public Invitation for testing and reviewing the new XB ball head series, declares a company that lacks arrogance and accepts well intended criticism for the betterment of their products.

On the other hand a few minor flaws cannot obscure the built quality, the great stability and the smoothness of operation under different loads.

Therefore, I consider the XB-44 Low Profile Ball Head a top product, which after a little refinement yet may be ranked above competition.

Disclaimer:

This review and test was run on a single product sample, using the specifically described methods. Although the findings are good and some overcame the expectations for the product, it can not be used as a rule, unless more samples of the same product are tested. Furthermore, similar comparison tests should be run with comparative capabilities products so as to reach a solid conclusion.

As this is a very innovative and interesting ball head design, I got carried away with the length of this review. I apologize and hope you found the article interesting and useful, thank you for viewing and your patience if you read so far.

Update: July 2012

Update: July 2012XB-44 Low Profile ball head is now available also as model XB-44DD2

with a DDH-02 Panning Clamp

Update: August 2012

Update: August 2012A Useful Friction Tool by Sunwayfoto

Update: October 2012

Sunwayfoto XB and FB Series Manuals Available for Download

All Photos & Photosynths: © 2012 S.C.Vlachos

Photos by courtesy of Sunwayfoto.com are individually tagged.

Availability:

The Sunwayfoto XB-44 with standard screw knob clamp, or model Sunwayfoto XB-44DD2 with panning clamp are available from Amazon or from eBay worldwide.

Meanwhile, as of 2022 you may also purchase directly from the Sunwayfoto Store starting from US$ 199.00 for the XB-44, US$ 219.00 for the XB-44DL and US$ 239.00 for the XB-44DDHi.

Please note that we may earn a commission from qualifying purchases through above affiliate links.

Relevant Articles:

Sunwayfoto DB-36TRLR Traveler Ball Head Review

Sunwayfoto DLC-42 Duo Lever/Knob Quick Release Clamp Review

Benro B-2 Ball Head Review

Triopo RS-3 Ball Head Review

Referenced Articles:

Benro A-298EX Versatile Tripod Review

Great review and I did in fact read this far!

ReplyDeleteThanks for your kind comment and for your patience indeed!

DeleteI'm very interested in purchasing a new ball head and found this review to be honest and thorough in respect to a sample size of one but hey no manufacturer is going to give out 50 products to test for free.

ReplyDeleteYou are absolutely right that no manufacturer is going to give out 50 products to test for free. However, I feel that a disclaimer mentioning the sample size, should be there to justify possible contradictions between reviews and as a measure of objectivity.

DeleteThanks.

Absolutely correct here.

ReplyDeleteJust another dumb question, so If I've got this right even when the bubble mount is removed, this particular clamping head if put into the drop notches will indeed interfere with the panning base and the ball stem can not be hard up or flush with the notch? Have I got this right here? Sorry.

ReplyDeleteThere is no interference between the bubble mount and the ball head base whatsoever, a problem arises only if you intend to use the head on a flat top tripod like a Gitzo sytematic or a Feisol where it will interfere with the tripod mounting plate being larger than the ball head base.

DeleteNow about the particular clamp, if you just fully drop the stem in one of the notches either forward or on the side (portrait position) there is no problem. But in the rare case you want to swing the tilted clamp in the notch, then the clamp corners interfere with the ball head panning base. I say rare, because after two years of using the head, I don't recall any occurrence. Especially if you use an L bracket on your camera you may never face the situation.

Nevertheless, in order to be thorough, I had to mention my findings in the review and let the reader weight the significance of the matter.

On the other hand, as you can see in the Sunwayfoto DDY-58 Discal Quick Release Clamp Review or the Sunwayfoto DDH-02 compact Panning Clamp Preview a discal clamp is most appropriate for such a low profile ball head.